|

The Periflex Era

Sir Kenneth began to

think about the possibility of producing a camera. The initial idea

was to produce a subminiature version of a 35mm camera using a 16mm

film cassette. A lot of development work was carried out, but it became

obvious that the concept was wrong. Such a camera would only sell in

comparatively small numbers and only a few dealers would stock, or

even print from, the film in the unique format. The project was

dropped, but the seed had been sown, and soon thoughts turned towards

a camera using 35mm film.

The initial concept was

to produce an economically priced, high quality 35mm camera body with

a focal plane shutter and a Leica lens mount, so that Leica owners

could purchase one for use as a second body. Another consideration was

that at the time there were a lot of second hand Leica lenses on the

market. This would make it possible for someone to purchase the camera

and a Leica lens, and end up with a high quality camera at an

economical price. In the early 1950's, import restrictions meant

that new Leica equipment was in short supply in the shops. A lot of manufacturers were

producing all kinds of accessories for Leica cameras, as it was often

very difficult to obtain the genuine article . It was possible to purchase almost any

accessory, but this was the first time that anyone had attempted to

offer a cheaper alternative to the camera body itself.

Work quickly got

underway. Many of the parts were made from aluminium instead of the

usual brass, as this was both cheaper and easier to manufacture. The

shutter was designed to work from a thirtieth to a thousandth of a

second using a fixed tension blind with a variable slit. It was made

from rubberised fabric. A glass film

pressure plate was incorporated as it was easy to polish and avoided

film scratches. Another innovation was the sprocket-less film

transport which simplified the wind-on mechanism and avoided jamming.

It had been decided to include some kind of reflex focussing system.

The difficulty was to fit it in the small confined space above the

shutter. Sir Kenneth's solution was to use a small periscope which

could be lowered behind the lens for focussing. This would allow the

user to view the central part of the image through the lens and so

focus the image. The periscope was then retracted and the photograph

taken. A separate conventional viewfinder was provided to compose the

image.

|

The camera top plate with the periscope in the

centre. The lever to lower and raise the periscope can be seen

just above the letter 'p'. |

The Corfields were

delighted with their new camera. The final design was so good that it

could easily compete with the competition as a product in its own

right. To sell it as just a camera body would severely limit its

potential in the marketplace, and so it was now time to find a

suitable lens. Initially the leading UK lens manufacturers were

contacted, but not one of them could produce a quality product at the

right price. The next step was to contact the European manufacturers,

but this became unnecessary after Sir Kenneth was introduced to

Frederick Archenhold. He was an experienced optician who worked for

the British Optical Lens Co. in Walsall. He suggested that Corfields

could make the mount and his company could make the lenses. They had

just installed new lens coating equipment and could easily mass

produce lenses to a high standard. After some thought Sir Kenneth

decided that this was a good option, and gave Frederick the go ahead to

design the optics and provide Corfields with a specification for the

mount. The lens mount and body were made of aluminium which could be

polished to provide a similar finish to the satin chrome finish which

was popular at the time. The new lens was called the Lumar and initial

prototypes performed extremely well.

New production

facilities were now required to manufacture the camera and lens.

Luckily the company was able to purchase one of its immediate

neighbours in Merridale Works to provide the much needed extra space.

New machinery was soon installed and everything was made ready for

production to begin. The first cameras had black anodised top and

bottom plates, and were finished in pigskin. The camera was named after

its unique periscope focussing mechanism and was called the Periflex.

John's workload was lightened during this expansion as he appointed

Eric Isles as technical assistant, and Gerry Whitton as toolmaker.

Prior to this John had personally designed, drawn and dimensioned

every component, and made all of the tools for the various products.

|

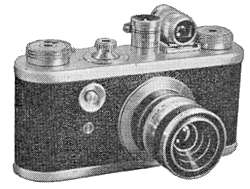

The original Periflex with black top and bottom

plates, and pigskin covering. Only the first 200 or so were

covered in pigskin. It was replaced by black leathercloth

which was easier to handle and more fashionable. |

| The black leathercloth version. The ring around

the shutter release can be unscrewed to allow the fitting of a

Leica-type cable release. The flash socket is now recessed

into the camera body instead of standing proud. |

|

The first the public

heard of the camera was a pre-launch article which appeared in the

January 28th, 1953 edition of Amateur Photographer. It consisted of

advance details supplied by Corfields and looked forward to the

appearance of the camera. The edition of May 20th was the first to

announce the arrival of the new camera. The write-up

included the following:

The camera has a

somewhat Leitz body style, but different in having the periscope

eyepiece and the unusual tan pigskin covering. The body is constructed

of 16 s.w.g. light alloy, has a removable back and base. Equipped with

a Leica thread lens mount, collimation had been carried out to a high

degree of accuracy to suit the widest apertures - plus or minus

0.0004in from flange to the face of the film plane. The camera was

very comfortable in the hand, with the shutter release being placed on

the front of the body in a natural position for the index finger of

the right hand. Around the shutter release was a removable collar

which, when unscrewed, would allow the fitting of a Leitz cable

release. Flash synchronisation was provided by the standard 3mm

co-axial socket. The prices were quoted as: body only £19.19.6d, with

50mm f3.5 Lumar lens - uncoated, £29.18s.6d, or coated £32.19s.6d.

The write-up was a

great success. As soon as the magazine reached the shops orders

started pouring in. It had only been planned to initially produce

between 25 to 30 units each week, and so the sudden demand came as a

bit of a shock. It took sometime to build up production, particularly

as the employees had to be trained in a lot of new skills.

|

After

approximately 18 months the camera underwent some cosmetic changes.

The top and bottom plates were silver anodised aluminium and the lens barrel

was simplified. Black leather strips were added to the adjustment

rings to allow the user to firmly grip them. These changes brightened

up the appearance of the camera, and gave it a more modern

look. |

|

|

|

|

|

|

Back |

|

Return

to the beginning

|

|

Continue |

|